Die casting has become an integral part of the process of production, providing the ability to combine high-end precision and efficiency to create complicated metal components that can be used in diverse industries. From automobiles to electronics Die casting is an important role in the development of contemporary technologies as well as infrastructure. This article explores the intricacies of die casting by examining the process, its benefits, applications and the constant advancements.

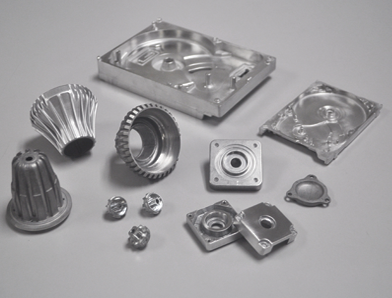

The fundamental principle behind die casting entails the injection of hot metal into molds known as dies under the pressure of a high. This method allows for development of complicated shapes and precise tolerances. This makes it perfect for the mass production of products that have consistent high-quality. Most dies are constructed of steel that has been hardened, that is able to withstand the extreme heat and pressure that is required in the process of casting. The material, typically zinc, aluminum or magnesium alloys, are melting in a furnace prior to it is injected into the cavity with high speed.

One of the major benefits of die casting lies in the fact that it can create components with exceptional precision and surface quality. The pressure that is applied during this process guarantees that melts of the metal flow through every nook and cranny of the die. This results in precise details and sharp lines. This degree of accuracy is especially important in fields like automotive and aerospace where the components need to be in compliance with strict performance requirements. Furthermore, die casting removes the requirement for a lengthy post-processing and reduces total production times and expenses.

The uses of die casting are found in a variety of sectors, which demonstrates the versatility and flexibility. Within the automotive industry Die-cast products are widespread and are found in engines such as transmission housings, transmission parts, and structural elements, due to their lightweight but robust characteristics. In the same way, the electronics industry utilizes die casting in making connectors, heat sinks as well as housings. In these cases, the electromagnetic shielding and thermal conductivity are essential. From electronic consumer products to industrial equipment Die-casting plays the key role in shaping the present-day environment. For more information please Find Out More

Recent technological advances in die casting have enhanced the capabilities and long-term sustainability. Vacuum-assisted casting for example, minimizes porosity within the final product and improves physical properties as well as surface finishing. Furthermore, the incorporation of automation and robotics improves efficiency in the manufacturing process improving efficiency while minimizing errors made by humans. Furthermore, efforts to design environmentally friendly alloys and improve energy consumption contribute to the industrial sector’s efforts to be sustainable, and align with global efforts to adopt sustainable manufacturing methods.

While it offers many benefits however, die casting isn’t free of challenges. Initial costs for tooling can be substantial, especially for intricate components with complex patterns. In addition, sustaining the tooling and maintaining the same quality during the entire production process requires an attention to detail that requires knowledge. But, advances in the field of computer-aided design (CAD) and software for simulation have allowed for a better understanding of these issues, and allow engineers to improve designs and anticipate potential problems prior to the start of production.